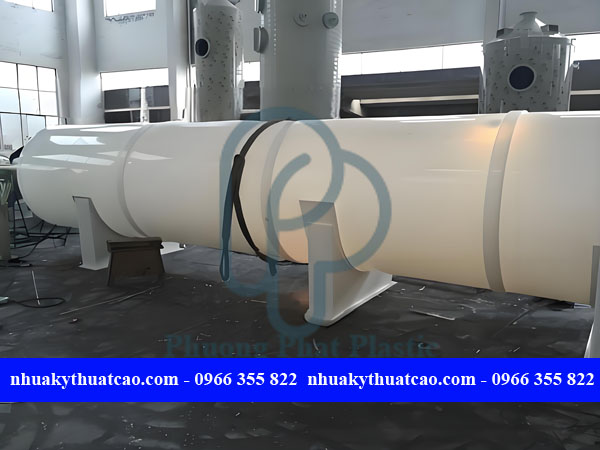

20M3 CHEMICAL PLASTIC TANK

Liên hệ để nhận thông tin tư vấn và báo giá

Thông tin sản phẩm

20M3 CHEMICAL PLASTIC TANK

20M3 CHEMICAL PLASTIC TANK for storing and handling chemicals have become a popular and effective solution for many industries. These products not only help to safely store chemicals but also demonstrate intelligence in design and manufacturing materials. From industrial plants to laboratories, plastic chemical tanks have become an indispensable part of production and research activities.

PLASTIC MATERIALS FOR PROCESSING 20M3 CHEMICAL CONTAINER PLASTIC TANK:

Chemical storage tanks are mainly made from materials such as PP (Polypropylene), PVC (Polyvinyl Chloride), and PE (Polyethylene). These materials are known for their corrosion resistance and oxidation resistance, making them ideal for storing chemicals such as acids or bases.

By choosing the right material, users can customize the thickness of the tank, from 3mm to 30mm, depending on the usage needs and the type of chemicals to be stored. This not only ensures the durability of the product but also creates a safer environment for workers.

Polypropylene (PP):

Polypropylene (PP) is a popular thermoplastic used in the manufacture of chemical tanks. PP stands out with the following properties:

- Good heat resistance: PP has a melting point of 160°C to 170°C, allowing use in many high temperature environments.

- High chemical resistance: PP has good corrosion resistance, especially to many chemicals such as acids, bases and solvents.

- Lightweight: With a specific gravity of around 0.9 g/cm3, PP is an excellent choice for applications that require lightweight.

- Good recyclability: PP can be recycled many times without losing its original properties, in line with the trend of environmental protection.

Polyvinyl Chloride (PVC):

Polyvinyl Chloride (PVC) is also a popular choice in the production of chemical tanks, with outstanding properties such as:

- Good chemical resistance: PVC has high chemical resistance, especially to chemicals such as acids, alkalis and solvents.

- High mechanical strength and stiffness: PVC is a hard plastic and has good tensile, flexural, and impact strength.

- Low manufacturing costs: With its simple manufacturing process, PVC is an economical choice for industrial applications.

- Good heat resistance: PVC can withstand temperatures up to 60°C, suitable for many industrial environments.

Polyethylene (PE):

Polyethylene (PE) is another thermoplastic widely used in the production of chemical tanks, with outstanding properties such as:

- Good chemical resistance: PE has good resistance to many chemicals such as acids, bases and solvents.

- High mechanical strength: PE is a plastic with relatively good hardness, tensile strength and impact resistance.

- Easy to process: PE can be easily processed by many methods such as injection molding, blowing, and forming.

- Low manufacturing costs: Due to its simple manufacturing process, PE is an economical choice for industrial applications.

Choosing the right material is an important step in the design and manufacture of chemical tanks, ensuring safe and efficient storage for different types of chemicals.

OUTSTANDING FEATURES OF 20M3 CHEMICAL PLASTIC TANK:

Plastic tanks are more than just storage; they play an important role in the handling and management of chemicals. With their resistance to corrosion and oxidation, these tanks minimize the risk of damage not only to the tank itself, but also to the surrounding environment and human health.

For example, in a food manufacturing plant, the use of plastic tanks for chemical storage can help to better control hygiene and safety factors, while minimizing the leakage of toxic chemicals into the environment.

Corrosion and oxidation resistance:

Thanks to the manufacturing materials such as PP, PVC and PE, plastic chemical tanks have good resistance to corrosion and oxidation. This helps protect the tank from damage caused by contact with corrosive chemicals, while preventing leakage and environmental pollution.

Enhance safety and hygiene:

Using plastic chemical tanks also helps to increase safety and hygiene in industrial environments. They help prevent spills and ensure that chemicals are stored safely, avoiding the health of workers and the surrounding environment.

Flexibility and ease of customization:

Another point to emphasize is the customization of plastic chemical tanks. Made from PP plastic sheets, users can easily adjust the size and shape of the tank to best suit their needs. This brings flexibility and optimizes space in factories and workshops.

Improve production efficiency:

Using plastic chemical tanks can also help improve production efficiency in many industries. They not only ensure the safety of chemical storage but also help optimize the process of handling, transporting and using these chemicals.

In short, plastic chemical tanks are not just a simple storage tool, but also a comprehensive solution to improve safety, hygiene and efficiency in industrial production activities.

MODERN DESIGN AND GOOD USE:

Another point to emphasize is the customization of plastic chemical tanks. Made from PP plastic sheets, users can easily adjust the size and shape of the tank to best suit their needs.

Not only that, the application of modern technology in production also helps improve the quality and safety of the product. Manufacturers are constantly researching and developing new technologies to enhance the features and aesthetics of plastic chemical tanks.

Customizable size and shape:

Using PP plastic as the main raw material, chemical plastic tanks can be customized in size and shape to suit the space and needs of customers. This allows users to optimize the layout and use of space in production facilities.

Application of modern technology:

During the production process, manufacturers are constantly improving and applying modern technologies. This helps to improve the quality, safety and aesthetics of the product. For example, advanced processing techniques such as injection molding, blowing and forming are applied to create plastic chemical tanks with high precision and finish.

Optimal design:

In addition to customizing the size and shape, designers also focus on optimizing the design of plastic chemical tanks. They research and apply solutions to improve the functionality, durability and aesthetics of the product. For example, integrating suitable valves, pipes and accessories helps users operate and maintain the tank more safely and efficiently.

In general, the ability to customize and apply modern technology in the production of plastic chemical tanks has helped to bring high-quality products, optimally meeting the needs of customers in many industries.

APPLICATION OF 20M3 CHEMICAL PLASTIC TANK:

In fact, plastic chemical tanks are not only popular in the chemical industry but are also widely used in many other industries, from agriculture to medicine. They can be used to contain wastewater before treatment, as raw material tanks in the food processing industry or simply as containers for chemical research activities in laboratories.

Wastewater storage and environmental treatment:

In the environmental industry, plastic chemical tanks play an important role in containing and treating wastewater before discharging it into the environment. They have good resistance to pollutants and toxic chemicals, and help control wastewater quality safely.

20M3 Chemical Plastic Tank Contains raw materials in the food industry:

In the food processing industry, plastic chemical tanks are widely used to store raw materials and chemicals needed for processing. These tanks not only ensure food safety but also maintain the quality of raw materials.

The use of plastic tanks in the food processing industry is important because they are antibacterial and easy to clean, helping to minimize the risk of contamination. Not only that, with modern technology, these plastic tanks are often designed without corners, minimizing the risk of dirt and bacteria accumulation.

20M3 Chemical Plastic Tank Support research and development in the laboratory:

In addition to serving in industrial production and environmental treatment, plastic chemical tanks are also widely used in research laboratories. They are used to store various chemicals for research, testing or small-scale production purposes.

The flexibility in design and variety of shapes of these tanks make them an ideal choice for laboratory applications. This is especially useful when the work requires a variety of chemicals and at the same time needs to be stored safely and effectively.

STANDARDS IN CHEMICAL STORAGE:

- Safety is always the top priority when working with chemicals, especially in the industrial sector. Choosing the right plastic chemical tank not only helps protect assets but also protects people and the surrounding environment from unnecessary risks.

- In addition to standards, risk assessment and the development of specific preventive measures are also an integral part. Businesses must conduct periodic inspections to assess whether there are any hazards from chemical storage.

- Simple measures such as training employees on how to handle chemicals, providing personal protective equipment, and installing an alarm system in case of an accident are essential. Creating a safe work environment not only reduces risks but also increases employee productivity.

PLACE OF PROCESSING 20M3 CHEMICAL PLASTIC TANK IN VIETNAM:

It is undeniable that plastic chemical tanks play an extremely important role in many industrial activities. They not only provide a high-quality solution for chemical storage but also contribute to protecting the environment and human health. With the continuous advancement in production technology and sustainable development, investing in plastic chemical tanks is becoming increasingly necessary and feasible for modern businesses. Thanks to the flexibility in design and the ability to serve a variety of different needs, plastic chemical tanks are not only a simple product but also an indispensable part in the sustainable development of the economy.from specific needs to safety standards, the management and application of plastic chemical tanks contribute to creating a more efficient and safer working environment.

PHUONG PHAT PLASTIC specializes in processing – manufacturing – repairing PE PP plastic chemical tanks imported from Korea and Germany.

FOR MORE DETAILS, PLEASE CONTACT:

PHUONG PHAT PLATIC

+84 966 355 822

www.nhuakythuatcao.com

nhuaphuongphat@gmail.com